Moldtech designs a new Mould for box culvert wet cast for the french market

The company was in pursuit of an innovative and flexible manufacturing solution that would empower them to efficiently produce various dimensions of a specific element, all while utilizing the same mold. This need arose from the desire to streamline operations, reduce costs, and enhance production flexibility, allowing them to quickly adapt to different project requirements and market demands without the need to invest in multiple, distinct molds for each product dimension. In particular, Moldtech was focused on the production of “Culvert wet” elements—a critical component in infrastructure projects, particularly in drainage and water management systems.

These elements require precise specifications to ensure proper function and integration into larger systems, making the ability to produce different sizes with the same mold a highly valuable capability. This modular solution would not only optimize the manufacturing process but also significantly reduce the time and resources needed to switch between production runs of different sizes, thus increasing efficiency and reducing waste.

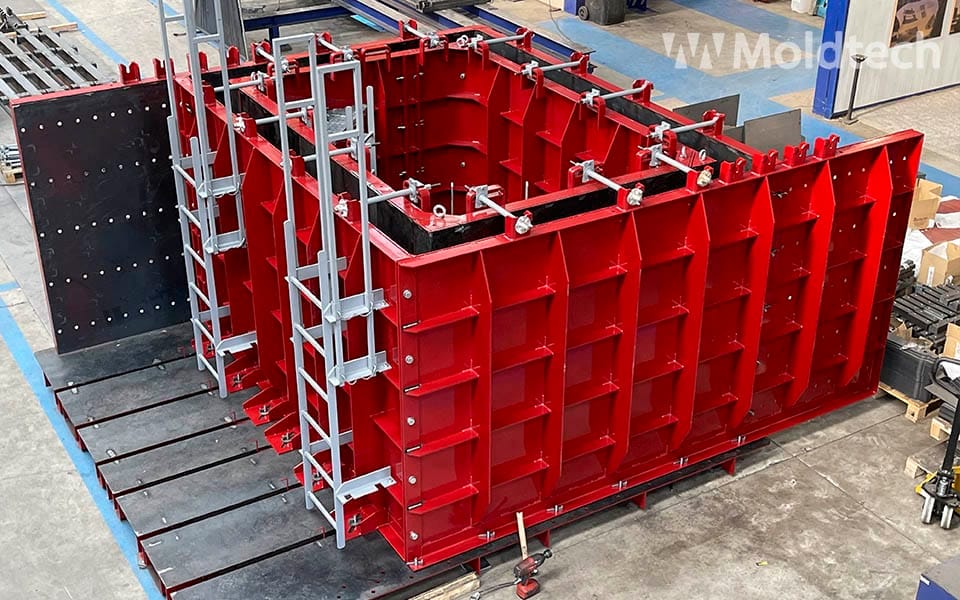

Versatile Mould Design by Moldtech for Customizable Box Culvert Production

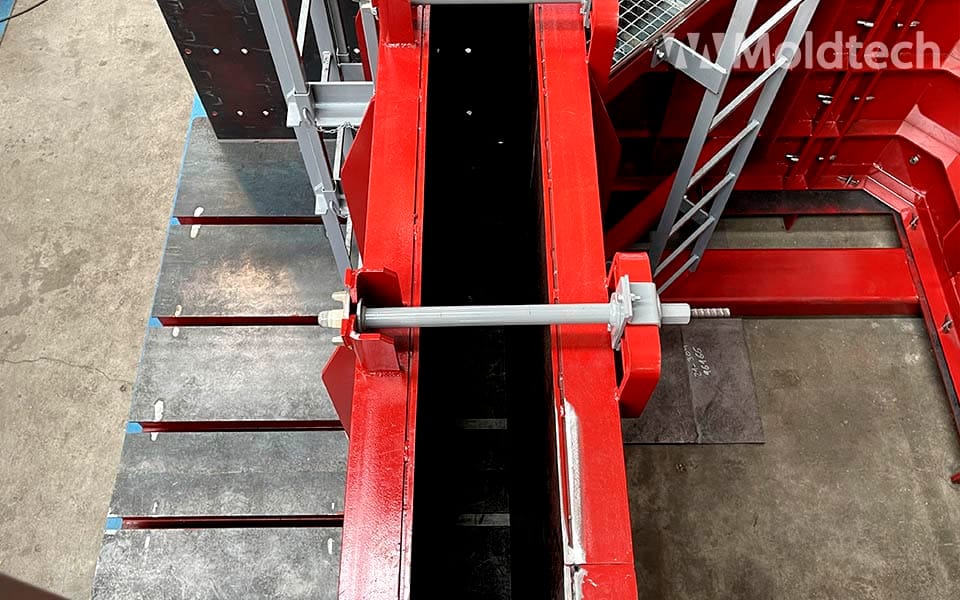

According with these specifications, the mould supplied by Moldtech, is an easy operated mould consisting in two “L” frame-shapes sides permitting to modify the sections and thickness of the element to cast, as well as a set of 2 bases to produce 2 pieces per day. The minimum interior section of the mould is 3 x 2 m, and the maximum is 3 x 3 m, having intermediate sections every 0,25 meters. Mould maintains the same height in all sections, while the thickness of the precast element could be also modified from 180 mm to 305 mm.

The combination of Moldtech know-how and this modular system allows the client to include attachments or supplements in the mould, getting the possibility of new dimensions and readjustment of the mould for future projects. In the meanwhile, this mentioned modularity permits demoulding in just few minutes.

Both companies are now studying together the possibility of supplying a second mould with similar features for increasing the production capacity of these mentioned box culvert wet cast.

Related entries:

Precast Concrete Mouldings power – Revolutionizing Construction

|